Failure Analysis

We at Met-Heat Engineers Pvt. Ltd. with the assistance of our skilled chemists, metallurgists, engineers, technicians, and our extensive experience in metal testing, heat treatment, metallography, knowledge of various codes, corrosion mechanisms, process knowledge, and fabrication expertise, along with the collaboration of experts from other relevant fields, are well-equipped to address your issues related to failure.

Our approach involves utilizing analytical and mechanical techniques, following a structured investigative process to identify the root cause of failure. Additionally, we provide recommendations to prevent future failures from occurring. We have successfully carried out numerous failure investigation projects. Prior to commencing the analysis, we engage with the client to strategize the failure analysis, taking into account the background of the failure and the key aspects of the investigation process.

Plan Followed For Failure Analysis

We follow a meticulous path for your failure investigation needs. The tests depend on the failure mode and material along with any other requirements by the client. An evaluation sequence of the process is summarised as follows:

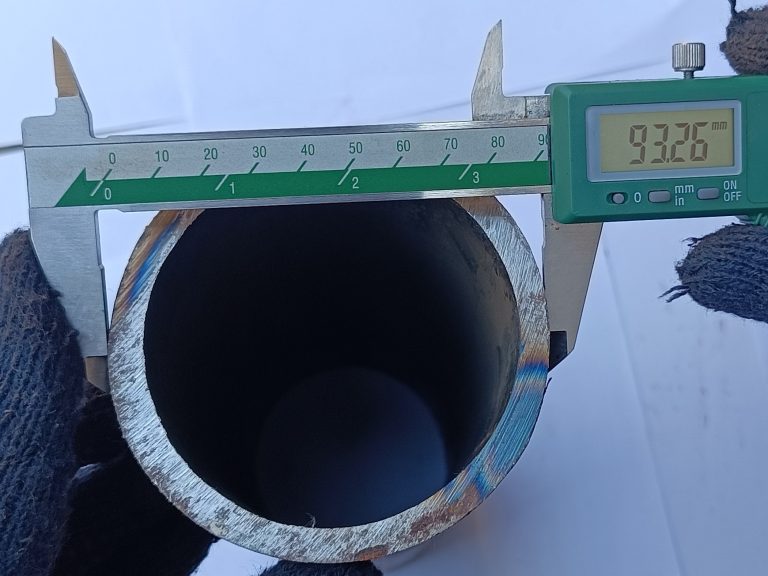

Collection of background data. History of failure, details of surrounding atmosphere, original material grade, material dimensions, etc are collected in form of a failure investigation data sheet.

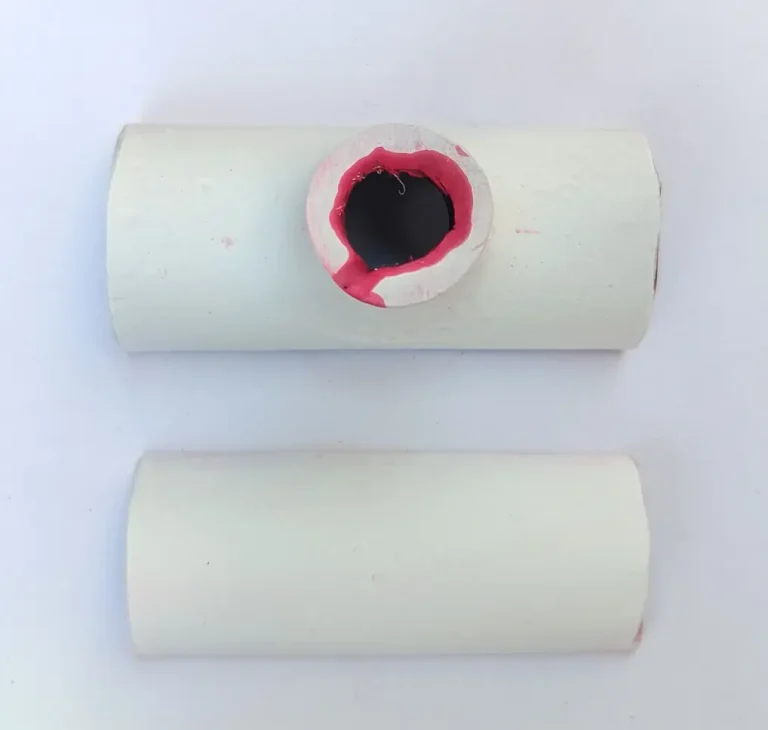

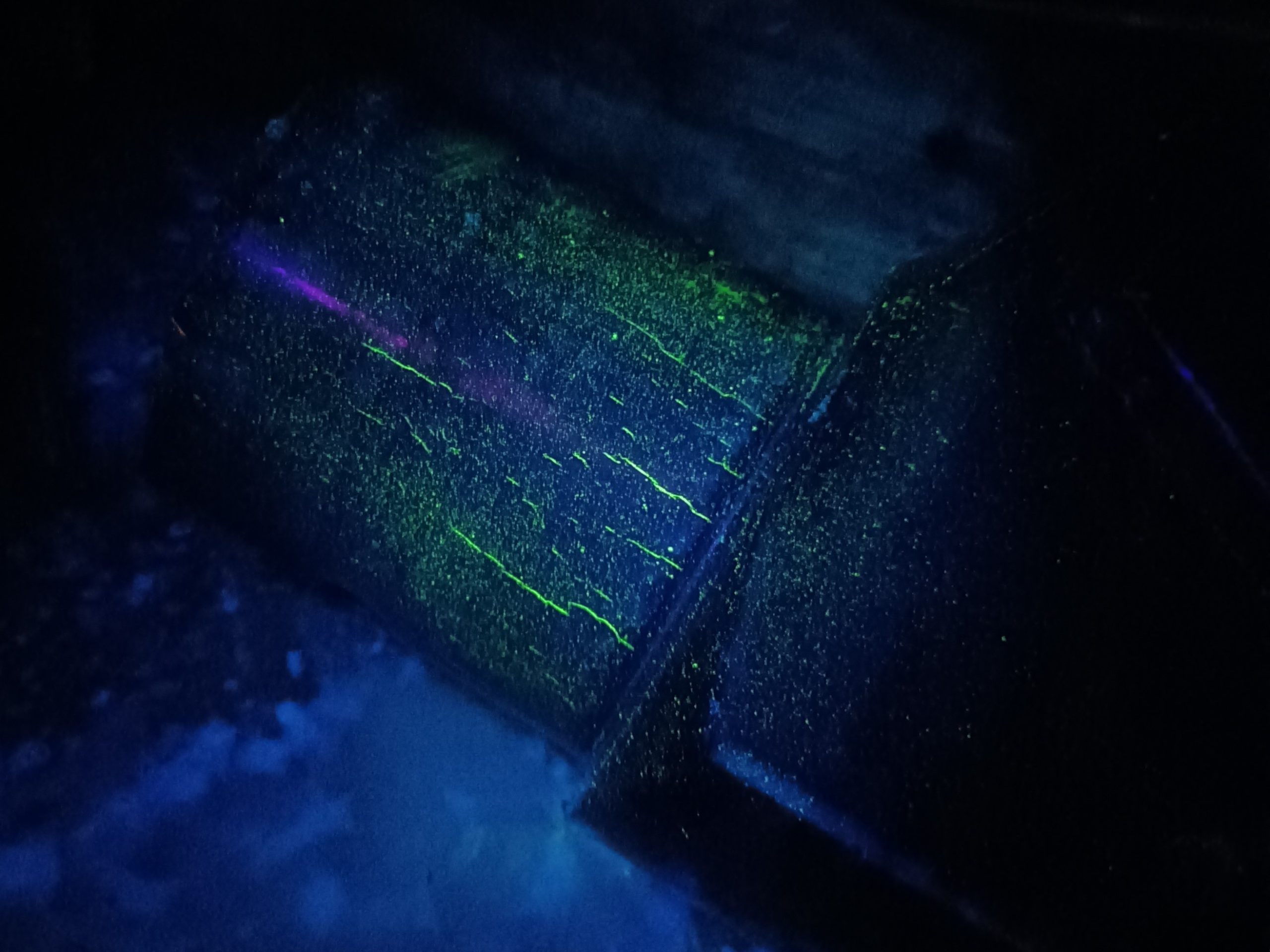

Examination of the failed part i.e. Visual Examination, Photography and or Videography.

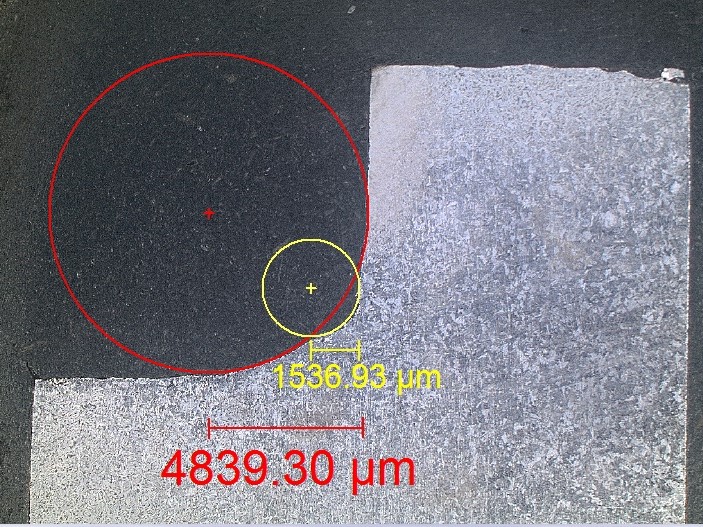

- Macro Examination

- Chemical Analysis (i.e. bulk, localized, deposit, rust, foreign particles, coating material, micro level analysis, XRF, etc.)

- Hardness Testing (i.e. at various locations & using various scale i.e. micro hardness to Brinell hardness)

- Mechanical Testing (i.e. Tensile, Bend, Rebind, Impact at various temperature etc.)

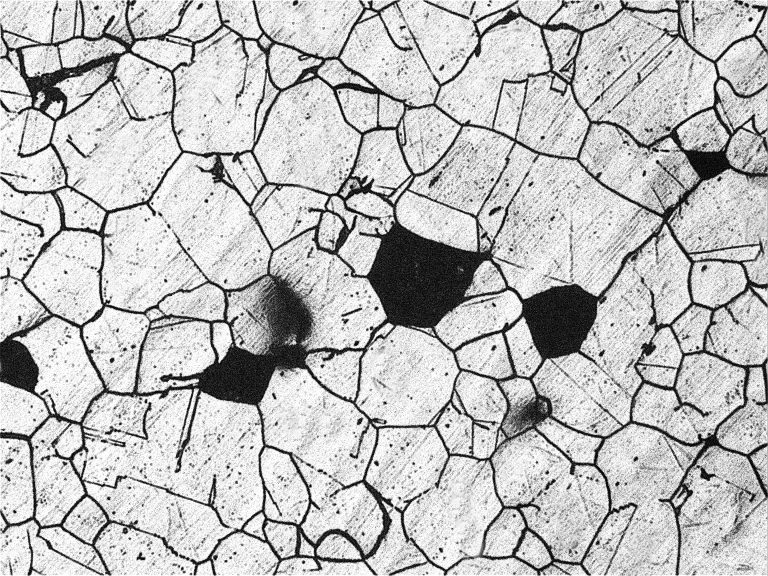

- Microstructure Analysis: At various locations, various cross sections, various magnifications with photomicrographs.

- Inclusion Content: at near & away from failure locations.

- Analysis of loading system /fracture mechanism/Design criteria

- Other tests, which has to be decided after the analysis results of above tests like SEM, EDAX etc.

A literature survey of material failure involves reviewing existing research, case studies, and technical papers to understand the common causes, mechanisms, and prevention methods of the material's failure.

Analysis of all the tests performed as above are discussed for its acceptance or rejection criteria & correlating all data.

From discussion & original background data decision of most probable cause of failure is determined.

To prevent such type of failure in future recommendations are given, if requested.